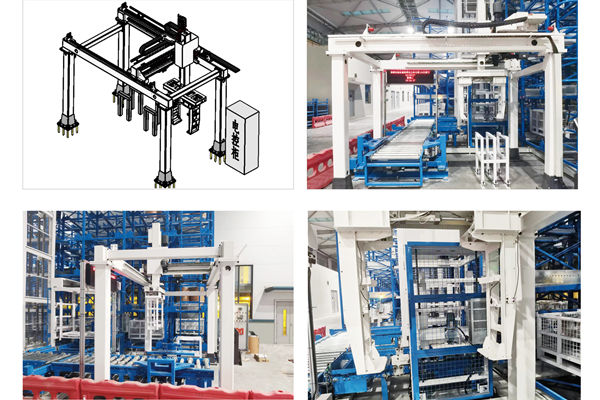

Using a three-axis truss robotic arm to replace manual labor, the welding wire barrel is automatically grabbed and transported to the designated position. This equipment has a compact structure, high positioning accuracy, safety and efficiency, and smooth operation.

The three-axis handling truss manipulator consists of X-axis, Y-axis, Z-axis, gripper, and column. The X/Y/Z-axis is driven by a servo motor to drive a planetary reducer and gear rack transmission, while the gripper is driven by a cylinder to drive a synchronous belt transmission.

Workflow:

1. The welding wire barrel is transported to the outlet;

2. According to the instructions, the truss robot unloads the entire welding wire barrel one by one and places it on the AGV pickup fixture, waiting for AGV pickup and completing the outbound process;

3. Automatic return of half palletized goods to warehouse; The empty tray automatically rotates to the encoder for automatic disc assembly.

The installation and handling of truss manipulators can replace manual labor, simplify the welding wire barrel conveying process, make the production line structure more compact, and improve productivity. Truman Company specializes in customizing various types of truss robots according to customer needs and actual situations. Welcome to inquire and order!